The world of marine textiles is fast evolving and it includes application of textile in marine applications such as sailcloth, ropes, boat coverings, awnings, flags. Safety equipment which are used in marine are also made from textiles which includes life jackets and inflatable life rafts, boat covers, decorative trim, exterior upholstery, flooring, headliners, ropes, nets, fabric, coated fabric & composites and so on. Apart from this, textiles are also used for making hoods, tarpaulins, protective covers, rear closures, but also for decorating and boat furnishings.

A not so talked about category, marine textiles have gained immense popularity over the years and commercial yachts that require premier textiles with a soft and luxurious hand to consumer fishing boats, pontoons and catamarans with seating crafted to protect against challenges such as microbial pinking, there has never been such an exciting opportunity for textile companies that serve the boating industry.

So, let’s take a closer look at the evolution of textiles within this sector and what lies ahead of the industry in terms of opportunity.

Building resilience

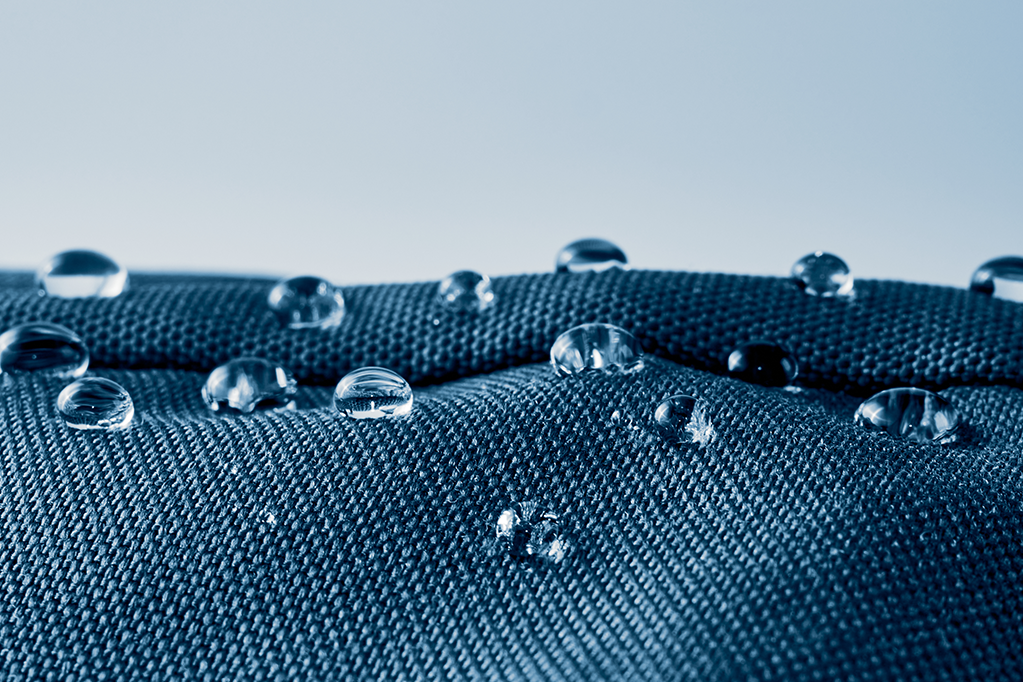

The idea of performance fabric is used broadly to refer to any textile designed to be easily cleanable and withstand wear and tear, but not all performance fabrics are created equal. Some rely on a sprayed-on topcoat or finish that wears away over time or after consistent exposure to ultraviolet (UV) rays from the sun.

The proprietary performance of most marine fabrics is engineered into the core of its fabrics with yarns saturated at the fiber level with exclusive UV-stable pigments. For example, Sunbrella marine canvas fabrics block 98 percent of harmful UV light. Traditionally natural materials such as fish nets and ropes were used to create marine textiles. The biggest disadvantage of natural materials is that they are heavy, absorb water quickly, and are prone to decay. This gave way to the discovery and construction of resilient marine materials. Canvas was one of the most preliminary fabrics used for the construction of marine fabrics, given its sturdiness and resistance to weathering. However, the landscape of the domain has altered considerably over time to bring in an array of innovative materials to the mix.

Looking into the demand

Performance is everything when it comes to marine textiles and many brands continue to push the boundaries of what’s possible with innovative marine fabrics. Innovation has no end when it comes to marine fabrics and many brands today are also experimenting with non-woven upholstery fabric to bring in a change. Many of the innovative fabrics today offer revolutionary resistance against microbial pinking, four-way stretch and recovery and serve lasting performance for years. What is important to note here is that the fabrics that suit the needs of the category have to be hardy and very strong. It also needs to feature a construction that is hardy, withstands tough environmental conditions and still stays strong, without getting misshaped.

Through research it has also been seen that the soft vinyl fabric is suitable for varied marine upholstery applications, including captain’s chairs, cushions, bench seating and sunpads. So, this is yet another fabric that finds broad usages in the industry today.

The growth of the category of marine textiles is inevitable, given the force and attention with which every brand in the sector is innovating. Moreover, following the lead of some of the key names, others are also changing their perspective, to innovate and build a stronger perspective for the category.